-

Project Title

BioMassify: Optimal Waste-to-Energy Supply Chain

-

Timeline:

45 Days

-

Tech Stack:

Python | CPLEX | Gurobi

-

Demo Link:

-

Client Name:

Project Detail:

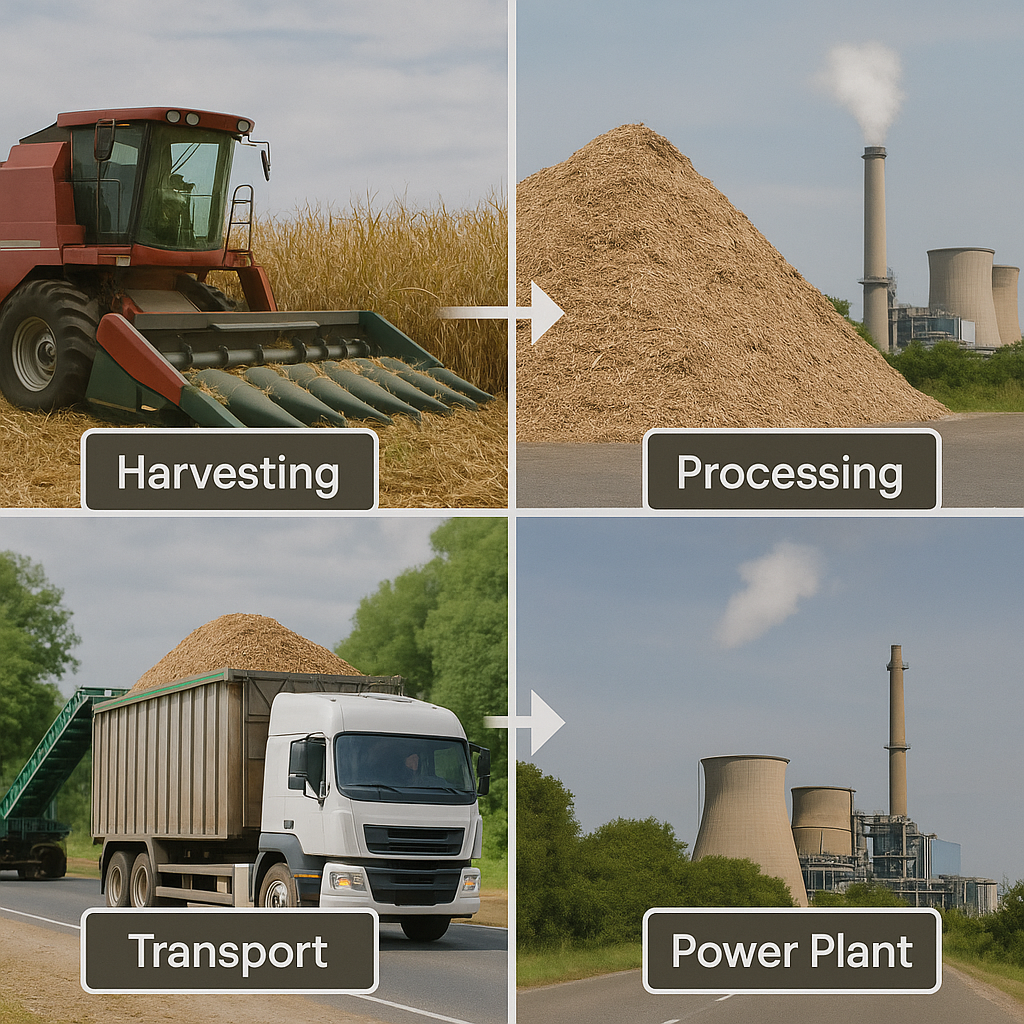

BioMassify aims to optimize the 'Waste-to-Energy' supply chain in the state of Gujarat, focusing on the conversion of residual biomass into biofuel. The project entails spatially forecasting biomass availability, then determining the best locations for preprocessing depots and biorefineries to maximize efficiency.

Problem Statement:

Given the variable spatial distribution of residual biomass in Gujarat, how can we forecast this distribution and identify the optimal locations for preprocessing depots and biorefineries to ensure a robust waste-to-energy supply chain?

Solution:

We employed a two-step approach. First, we utilized spatial data analysis and prediction algorithms to forecast the distribution of biomass in Gujarat. Next, using operations research techniques, we determined the optimal locations for the depots and biorefineries, considering factors like transportation costs, biomass availability, and potential biofuel demand.

Features:

- Spatial Biomass Forecasting: Predict biomass availability across different grid blocks.

- Supply Chain Optimization: Determines the best locations for assets in the supply chain.

- Scalable Model: Adaptable to other regions and varying biomass sources.

Use Cases:

- Government Initiatives: For policymakers aiming to promote renewable energy in specific regions.

- Biofuel Companies: Companies looking to establish a presence in regions with ample biomass availability.

Data Science Specific Points:

- Data Collection: Data on past biomass distributions was collected from regional agricultural databases, supplemented with weather and satellite imagery data.

- Data Analysis: Used machine learning algorithms, especially regression models and neural networks, to forecast biomass distribution.

- Results: Achieved an accuracy of around 88% in predicting biomass distribution across Gujarat.

Operations Research Specific Points:

- Objective: Minimize total operational costs while satisfying the demand of biorefineries.

- Variables and constraints: 300+ decision variables (biomass quantities, transportation routes, etc.), and 150+ constraints (availability, demand, etc.)

- Methodology: Linear programming was employed to solve the optimization problem using Gurobi.

- Performance matrix: Reduction in transportation and operational costs by 20% compared to non-optimized models.

- Model results: Identified 5 optimal locations for depots and 3 for biorefineries in the Gujarat region.

Technologies Used:

- Programming Languages: Python

- Frameworks: Scikit-learn, TensorFlow

- Solver: Gurobi